-

VAUXHALL - ROTARY ENGINE

PROJECT

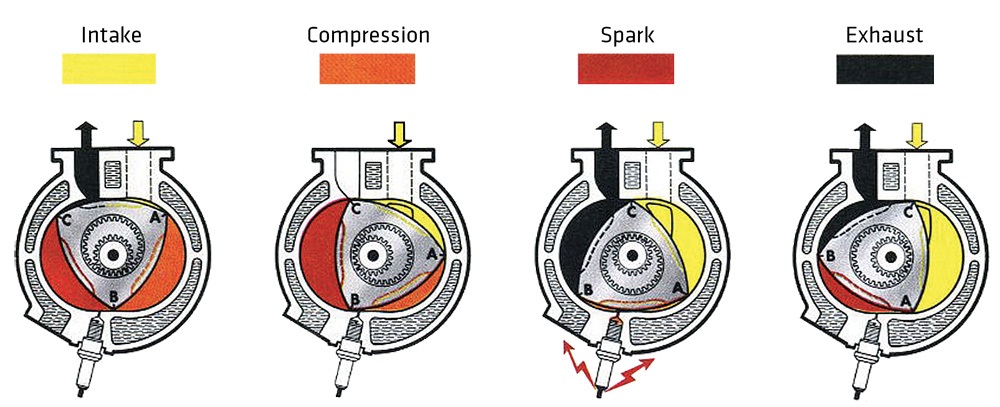

The General Motors Rotary Combustion Engine (GMRCE) was the project

name given to the engineering work carried out on the Wankel engine

which uses a rotary design to convert pressure into a rotating

motion instead of using reciprocating pistons. Several NSU and

Mazda rotary engines were procured in the late 1960s by GM Advanced

Engineering Division and stripped down and analysed for viability

versus conventional piston engines. The initial results were

promising due to the huge savings in weight and engine refinement.

As a result of these preliminary findings GM paid $50m for an

initial license to

produce their own version of the rotary engine. GM president Ed

Cole initially projected a commercial release within three years –

later to be seen as a very rash statement. Chevrolet were the lead

division with Pete Estes, John DeLorean and Cole all giving their

support for the project. A highly experienced engineer Bob Templin

was made the chief executive in charge of rotary-engine research at

the GM Tech Centre in Warren Michigan but Ed Cole would leave his

office in Detroit twice a week for the trip to Warren so he could

take chrge and minitor the progress of the programme. The engine

was initially targeted for an October 1973 introduction in the 1974

Chevrolet Vega as an engine option or standard in a sports

version.

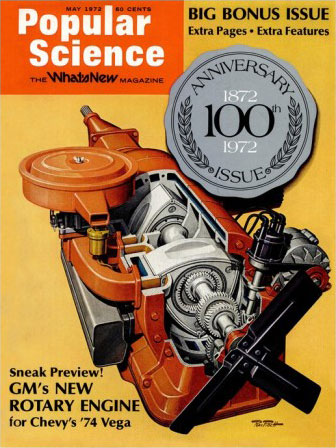

THE COVER OF POPULAR SCIENCE MAGAZINE WHICH MADE BOLD PREDICTIONS

FOR THE FUTURE OF GENERAL MOTORS ROTARY ENGINE - WHICH WERE ALL

WRONG IN THE END!

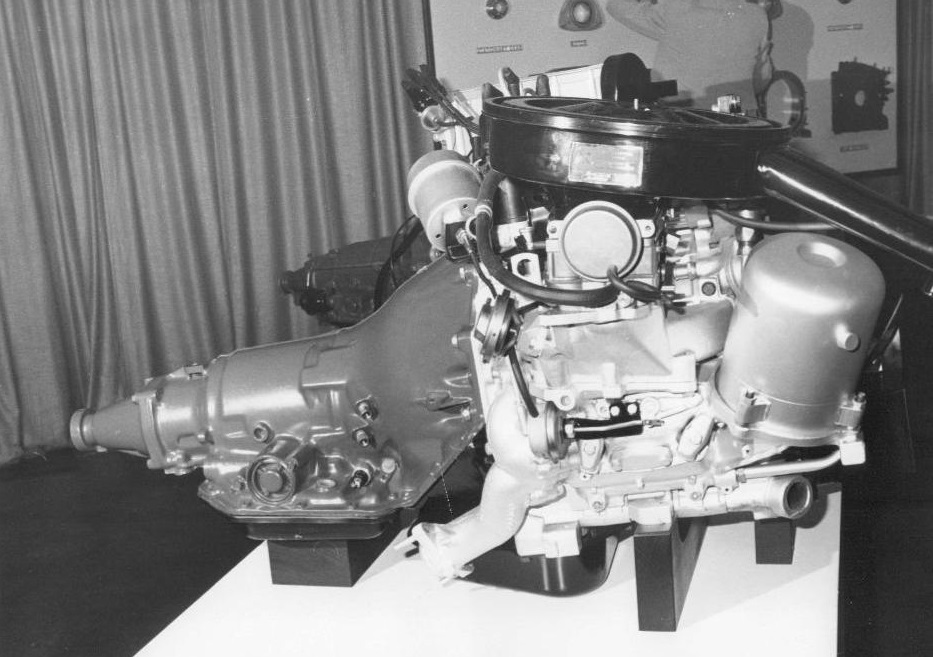

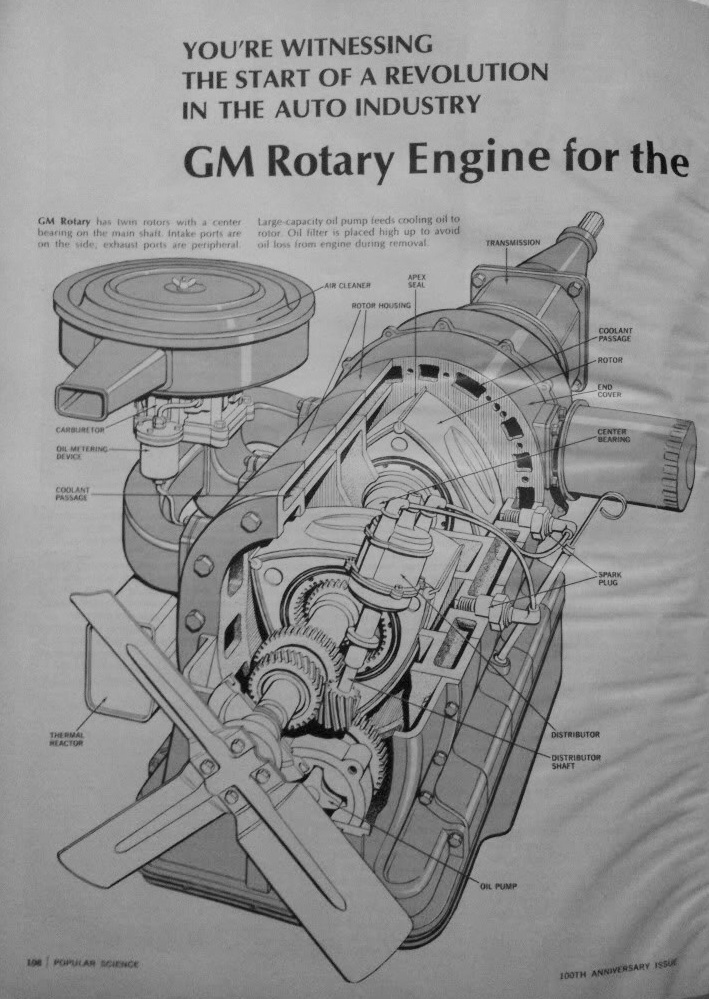

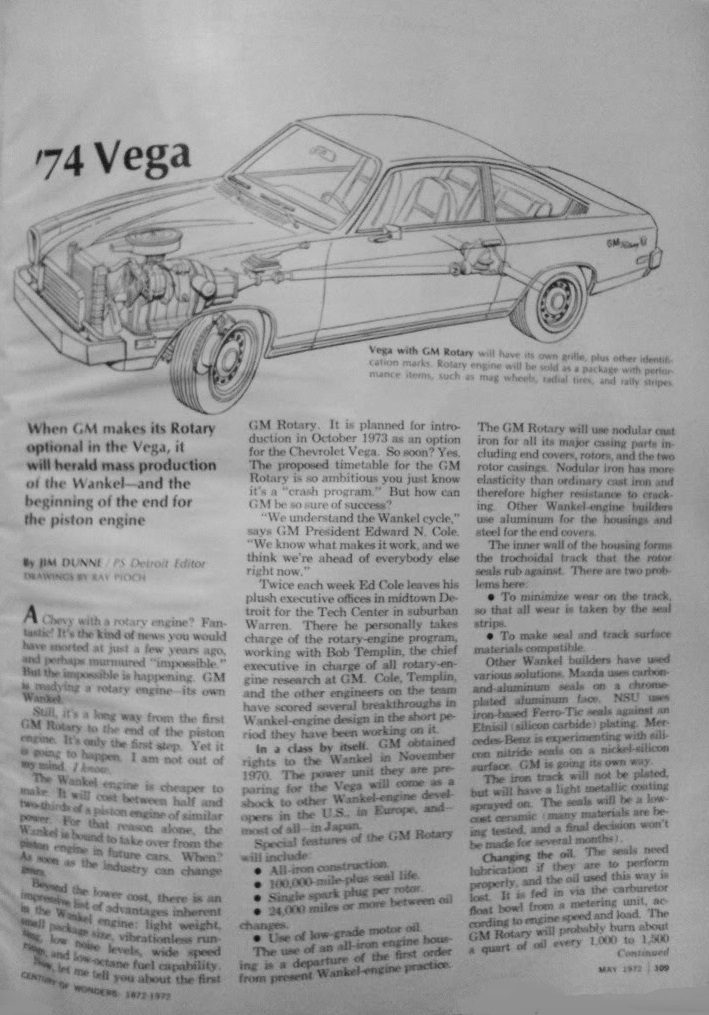

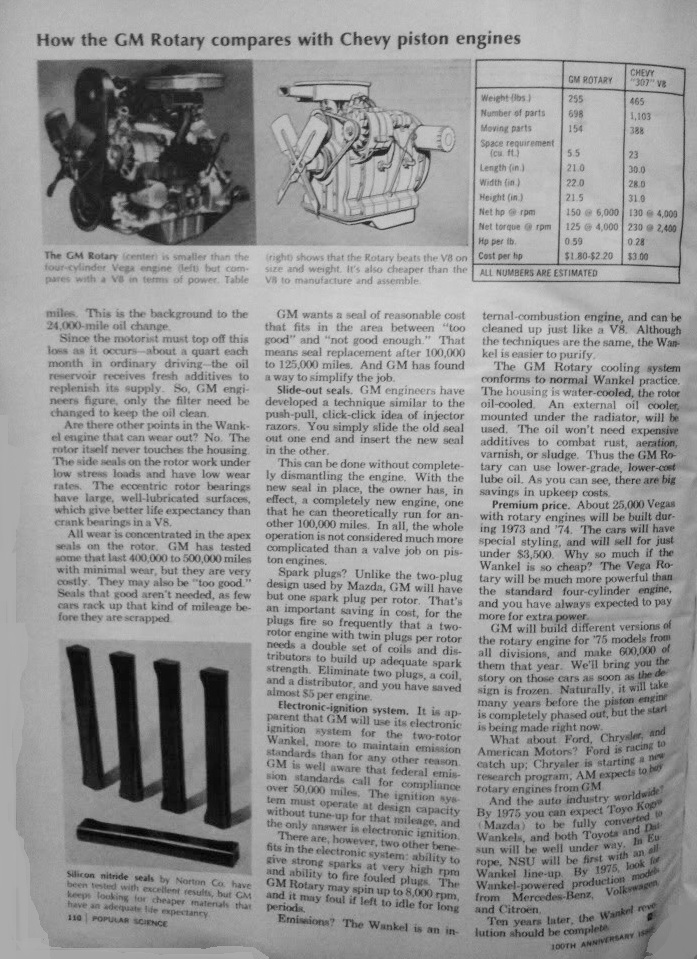

Further publicity was given in Popular Science magazine in May 1972 with an article titled “GM Rotary Engine for the 1974 Vega" complete with an illustration of the Wankel installed in a 1974 Vega hatchback using a different grille, a lower, more sloped hood line, and a "GM Rotary" badge and Wankel crest on the rear quarter panel. It was stated the Vega-rotary would be sold as a package with performance items, including mag-styled wheels, radial tires, and rally stripes. In durability tests the Wankel had so far proven more reliable than four, six, and eight-cylinder engines – GM-rotary engines were run up to 500,000 miles (800,000 km) showing only minimal wear, and the engine's fewer moving parts assured its reliability. The final design General Motors Rotary Combustion Engine (GMRCE) was fixed when responsibility for the power plant's manufacture was turned over to General Motors Hydra-Matic Division in August 1972 – two rotors displacing 206 cubic inches, twin distributors and coils, and a switch to aluminium housing construction. Iron couldn't match the heat-dissipating qualities of aluminium. In addition, there was also a rotor tip-seal problem in the cast-iron

configuration, especially after 15,000 miles. RC2-206 Wankel

engines were installed in 1973 Vegas for cold weather testing

performed in Canada. To assist with development it was at this time

that Vauxhall were made the lead division for rotary engine

research for all overseas divisions outside North America.

Considerable studies and evaluation exercises in conjunction with

Chevrolet were done at Vauxhall’s Engineering Centre at Luton using

modified NSU Wankel engines in the late 1960s and then experimental

GM RC2-206 rotary engines in the early 1970s. Initial development

was aimed at meeting European emission standards which at the time

were lower than the US combined with acceptable fuel economy and

was in hand when GM decided to defer the project in late 1974 — the

same time that they decided to drop production plans at Chevrolet

and centralise rotary technology at GM Engineering Staff because of

the oil crisis. A number of these GM RC2-206 rotary engines were

installed in Vauxhall cars, one in a manual Firenza and two in FE

Ventora automatics. GM in the US carried on developing the rotary

in diesel, stratified charge and fuel injected form, but it still

had a five or six per cent fuel economy penalty compared with a

conventional spark ignition reciprocating

engine.