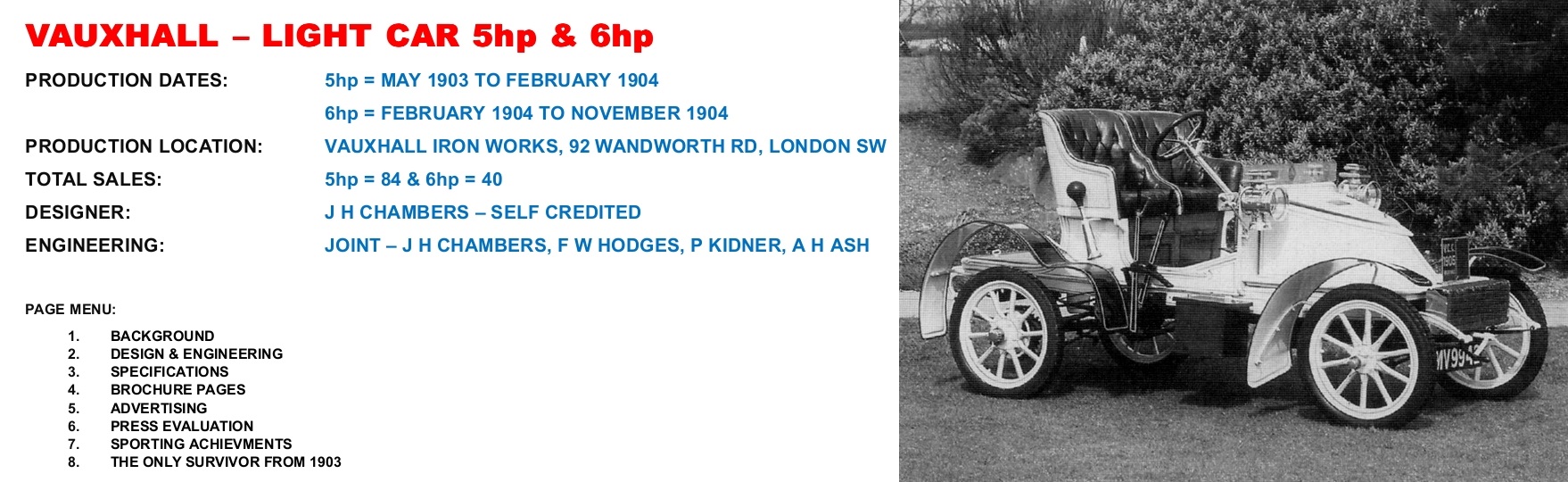

1. BACKGROUND:

The first British motor car had been produced shortly before 1896, by 1900 they were becoming a more familiar sight, especially in and around London, and FW Hodges and his fellow principle shareholders were not slow to visualize the huge opportunities which this new invention presented. Following a motor car fact finding trip around Europe by JH Chambers, and treading the same path as Henry Royce, a new motor car was purchased late in 1901, a Benz, and evaluated and tested by Chambers, Hodges and the new Works Manager Alfred Ash. Ash was an experienced marine engineer & naval architect and had joined the shortly after the last company reorganisation. Early in 1902 the car was stripped down and thoroughly examined and studied with the idea of Vauxhall eventually producing an improved but independent design. Another key figure at the Vauxhall Ironworks at this time was Percy Crosby Kidner, born in 1878 Kidner had briefly served with an architectural practice before serving an engineering apprenticeship and then studying the subject at Crystal Palace School of Engineering, he also had marine experience before joining the company. Along with many at Vauxhall he was enthusiastic about the fledgling motor car industry, over many years he would have a profound influence on the future of the company. The Benz car that was dismantled had a rear engine, tube ignition and belt drive, which obviously didn’t impress any of the company engineers as it bore no relation to how the first Vauxhall car was developed.

2. DESIGN & ENGINEERING:

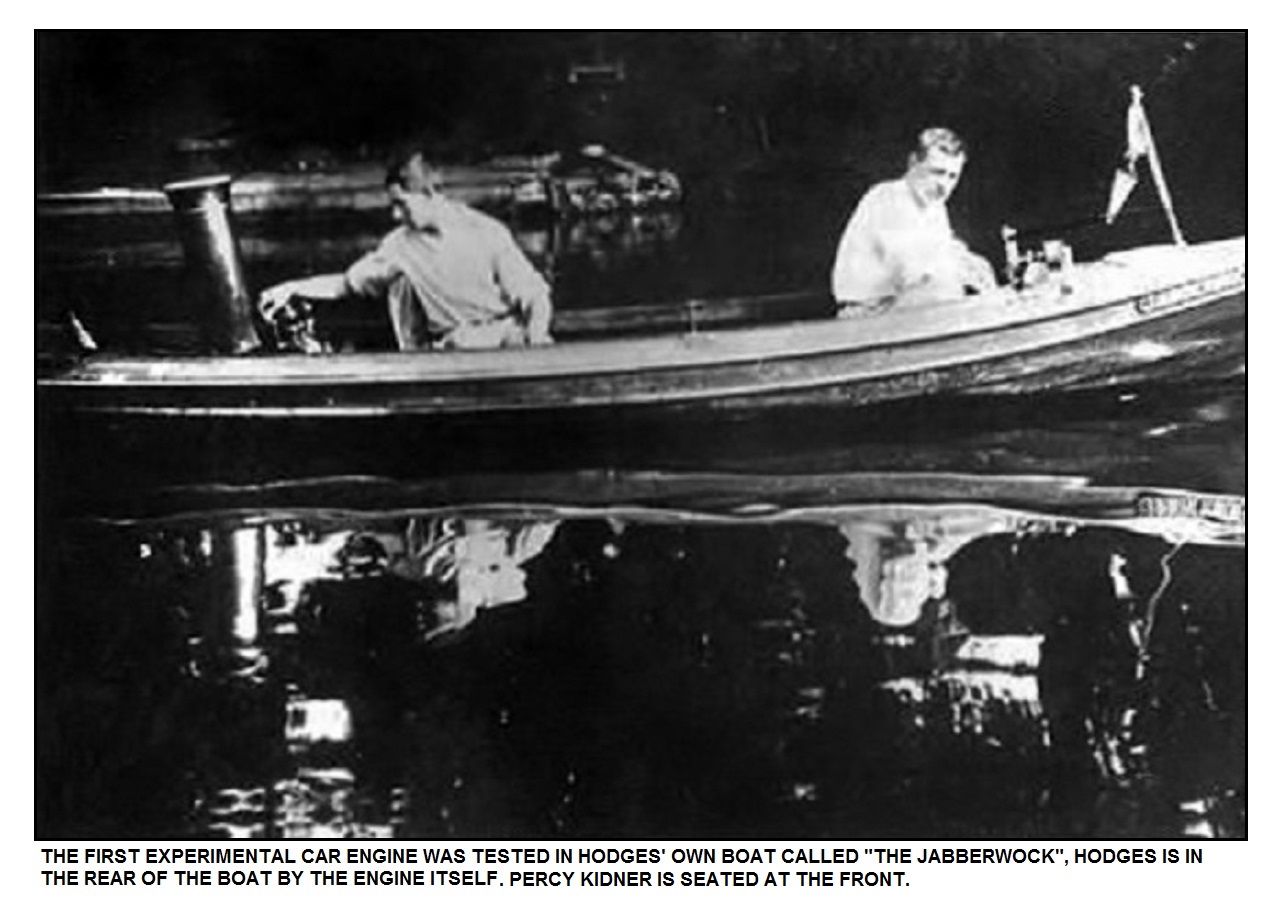

The first step towards the design of any type of motor car was the development of a suitable petrol engine. During the early part of 1902 both Chambers and Hodges were closely involved in the design & building of a prototype petrol power unit. They experimented with converting several stationary and marine engines that were produced by the company but this proved wholly unsuccessful. Starting from scratch, a small single cylinder engine with two opposed pistons was designed and built in a very short time with Percy Kidner playing an important role during the initial development. The first experimental engine was tested in Mr Hodges small river launch, the “Jabberwock”, and gave good enough results to encourage further experiments and to continue engine development. It was also around this time that an experimental five-cylinder radial engine was built but proved unsatisfactory due to cooling and lubrication problems and no further development work was carried out. Amazingly Hodges & Kidner also experimented with a design of a type of rotary engine but this too proved unsuccessful and in the end it was agreed that work would concentrated on a simple single cylinder / single piston engine. After many tests the final version was a 978cc and gave 5bhp, the single cylinder was water cooled and would be mounted horizontally under the dash with its cylinder pointing to the rear. It adopted atmospheric inlet and mechanical exhaust valves and the engine speed was regulated by a centrifugal governor. Vauxhall's own spray carburettor was used and ignition was by trembler coil and battery.

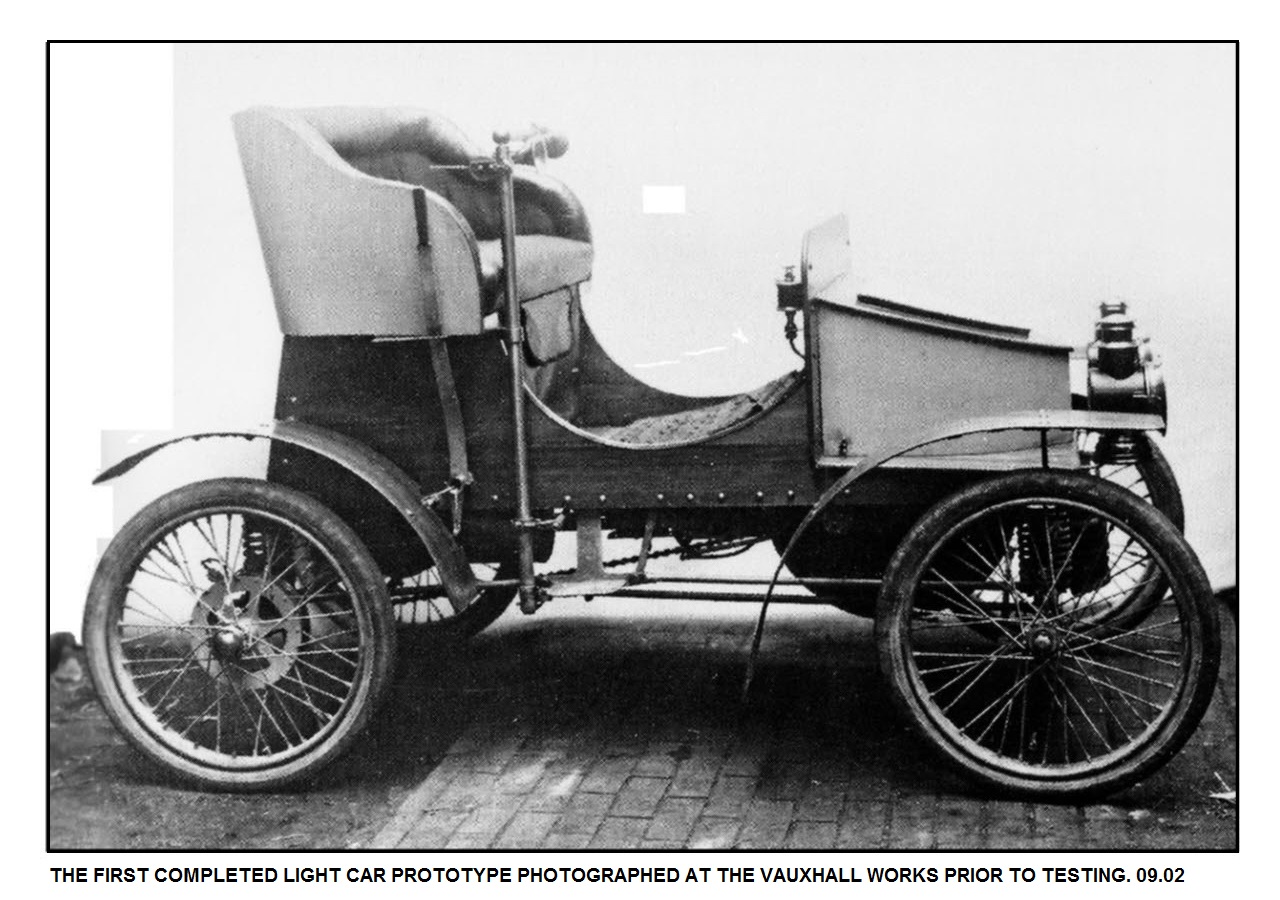

Next came the design layout for the complete car,

rapid progress meant the first prototype was running in September

1902 and completed many test runs which provided vital information

on design changes & highlighted numerous areas that needed

improvement before it could be offered for sale. The main engineer

who worked on the project day to day was Harry Pratt, a pioneering

and highly experienced machinist and metalworker. In an age before

modern mass production / construction methods he and his small

select team would have effectively built the whole car, including

the engine, from scratch following detailed design drawings from

Hodges and Ash.

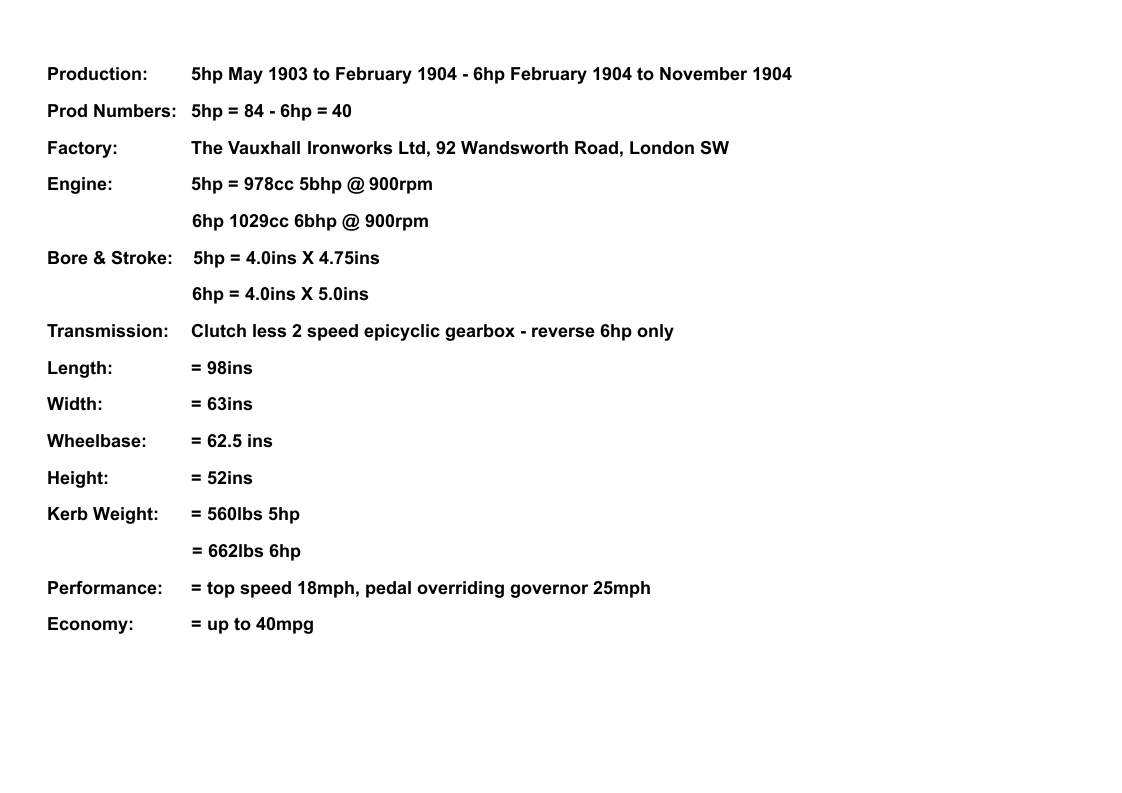

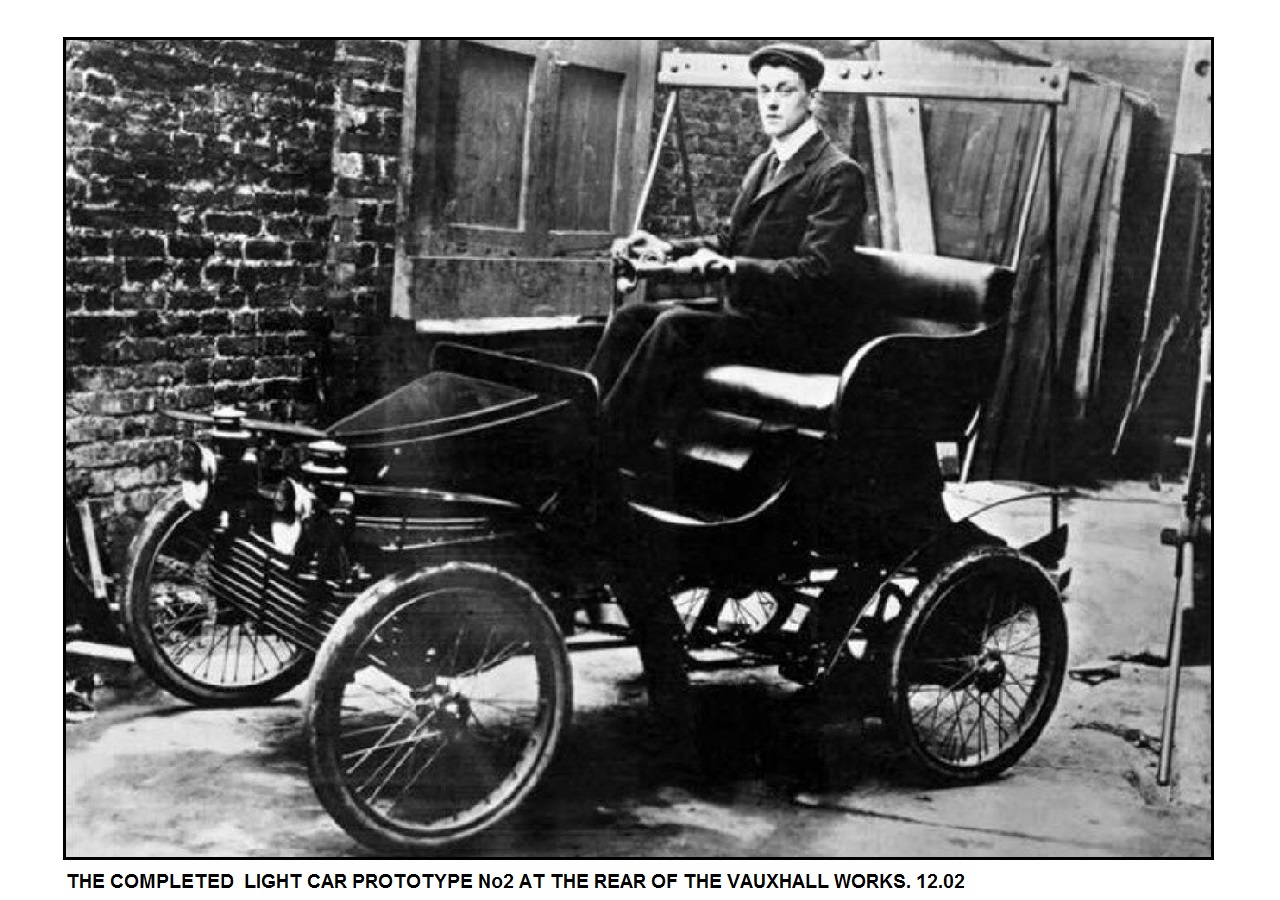

The second prototype Light Car was completed and started testing in November and proved to be reliable and efficient, reliability trials and development continued into 1903 and by early April the company was sufficiently confident to commit to the production of a batch of 12 cars to be offered for public sale at 130 guineas each. The price of £130gns with Dunlop tyres would be roughly £8000 in today’s money and represented good value at the time compared to rivals. The Light Car was intended to weigh less than 5cwtbecause of a law allowing it to dispense with a reverse gear, however despite missing this weight cut-off by 50 lbs it was still sold only having 2 forwardgears with no reverse. Curiously, in the very few 3 seater models that were produced 1 of the passengers actually sat ahead of the driver over the engine and added even more to the weight.

The body design of the Light Car did not look in any way radical, quite generic in fact, but as Hodges and Ash were both marine engineers, and knowing that weight would be critical, they created the first uni-body construction. It was designed on marine principles with a frame-less body like that of a boat, because to them this was the logical way to do things. Just as radical was the decision to amalgamate the chassis and the lower part of the body into a composite steel and wood structure whilst other car manufacturers at the time continued to rely on what was essentially bicycle frame technology. Most historians credit the 1922 Lancia Lambda as the first unit or monocque body, but Jan P. Norbye, in Special Interest Autos (Aug-Oct 1973) correctly gives the honour to Vauxhall. The marine connection was also the reason for the choice of tiller steering, as opposed to a wheel, with the accelerator control on the tiller. The suspension was by vertical coiled springs at each corner of the body, again unusual and advanced for the time, and again was probably used in order to save weight. Drive was by a durable chain to the rear wheels via a two speed gearbox, the lower ratio was achieved by using an epicyclic extension of the crankshaft and operated by a lever on the tiller column. The brakes used leather lined shoes and were congenitally mounted on the rear wheels and operated by both a hand lever & foot pedal. Although many other manufacturers adopted proprietary parts, or blatantly copied other manufacturer’s components, Vauxhall proudly boasted that their new 5hp model was designed and manufactured throughout “in house”

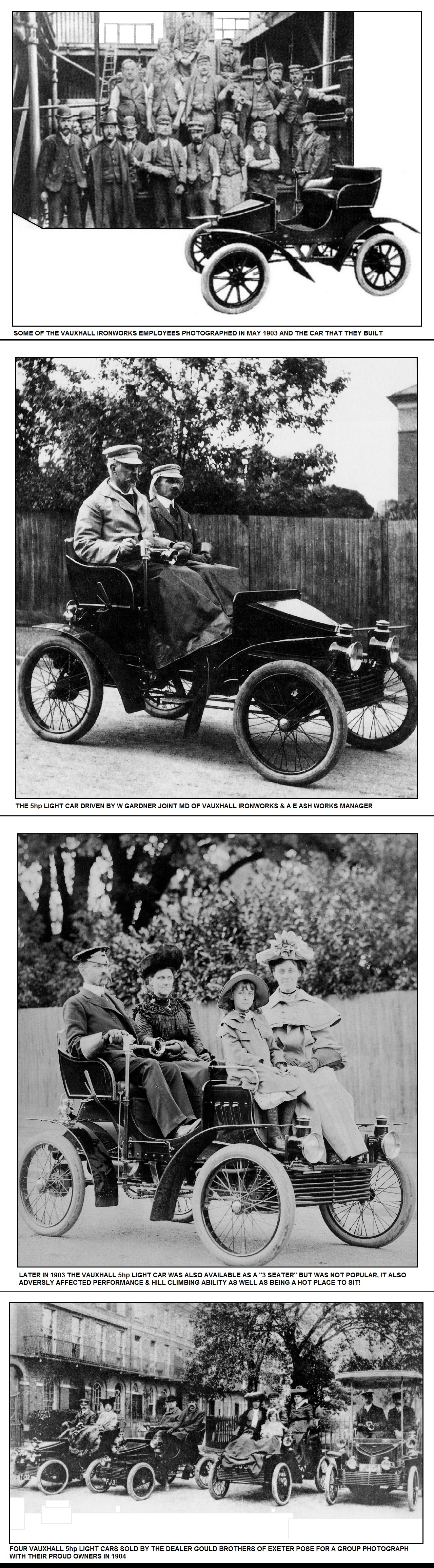

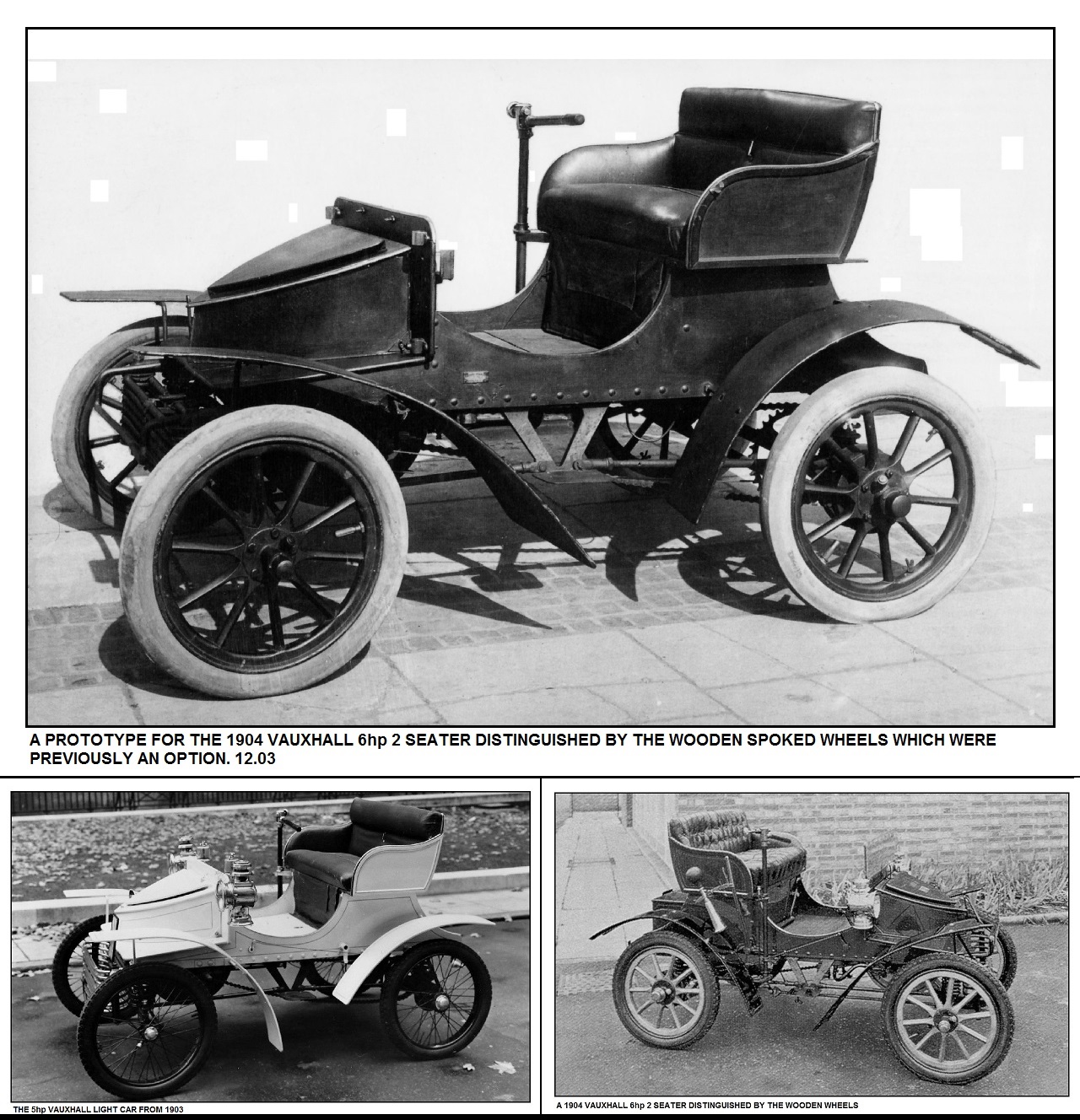

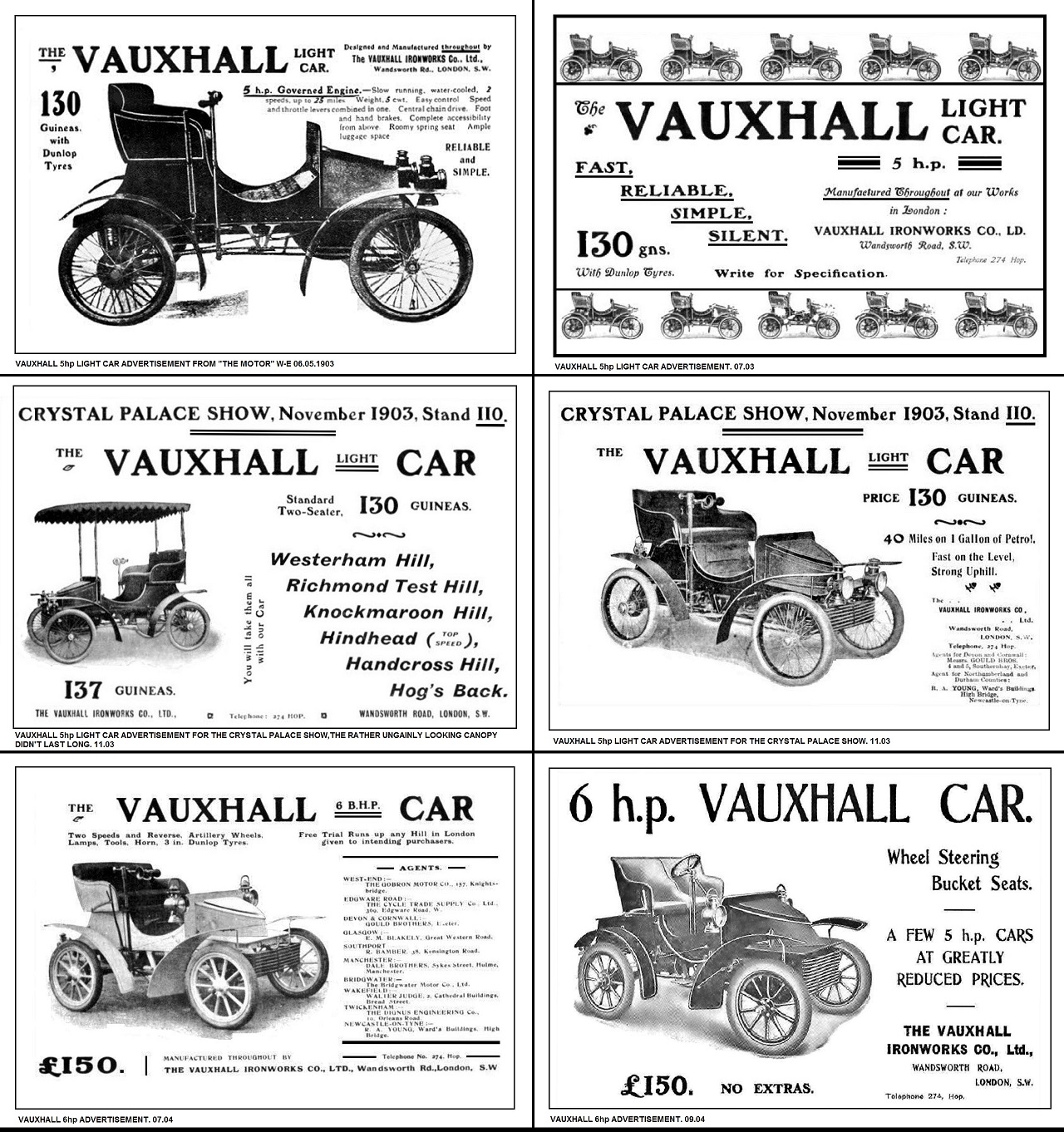

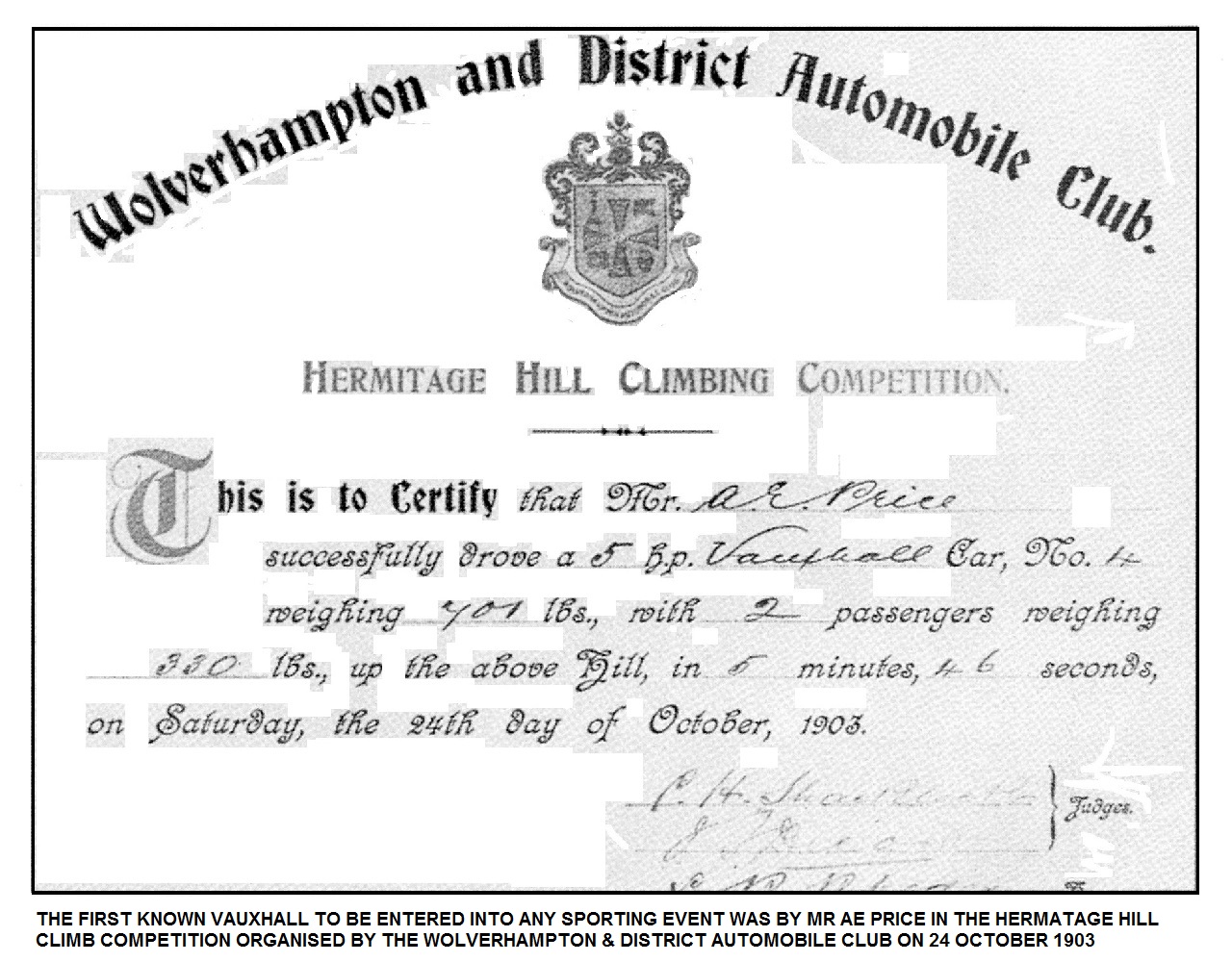

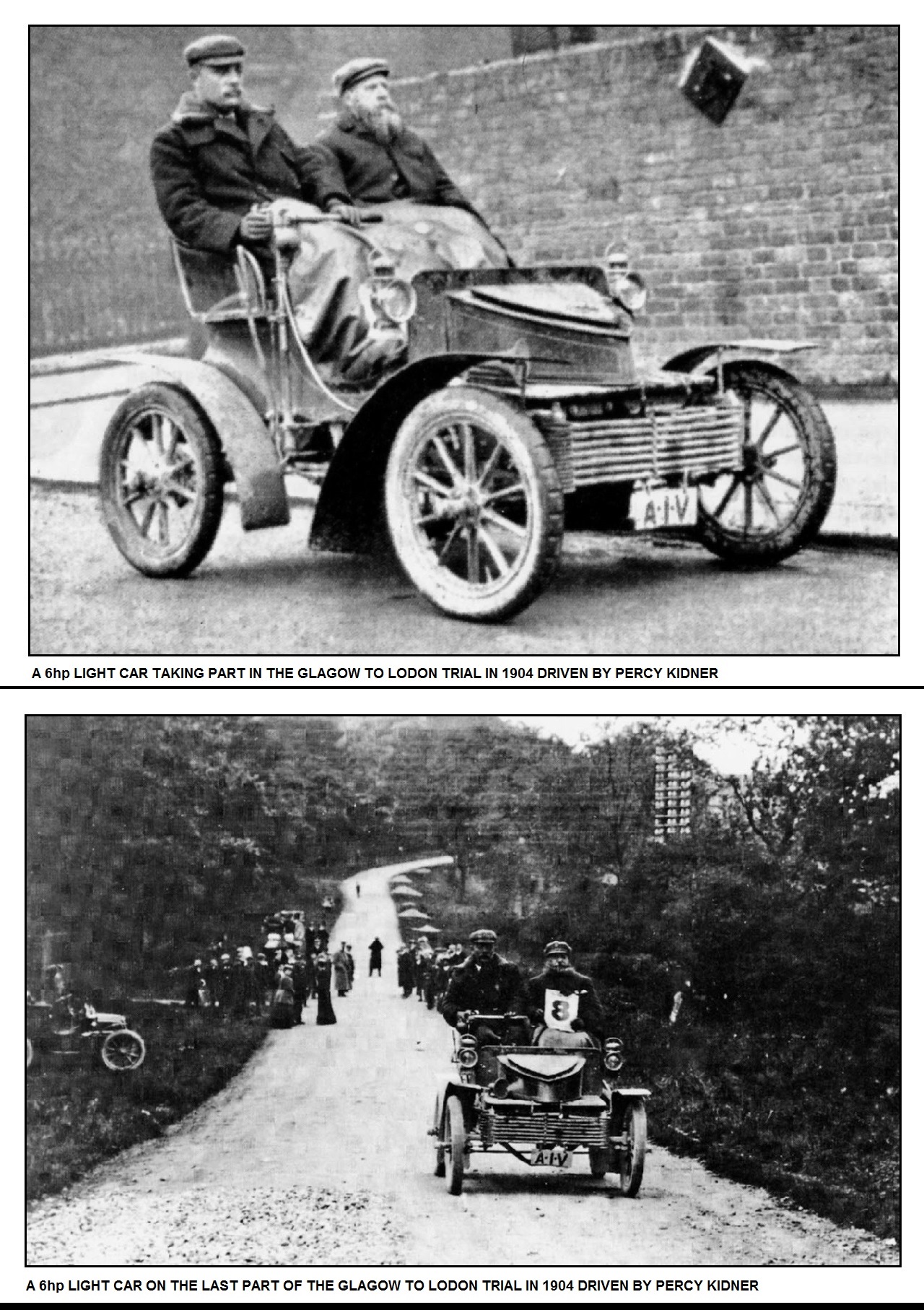

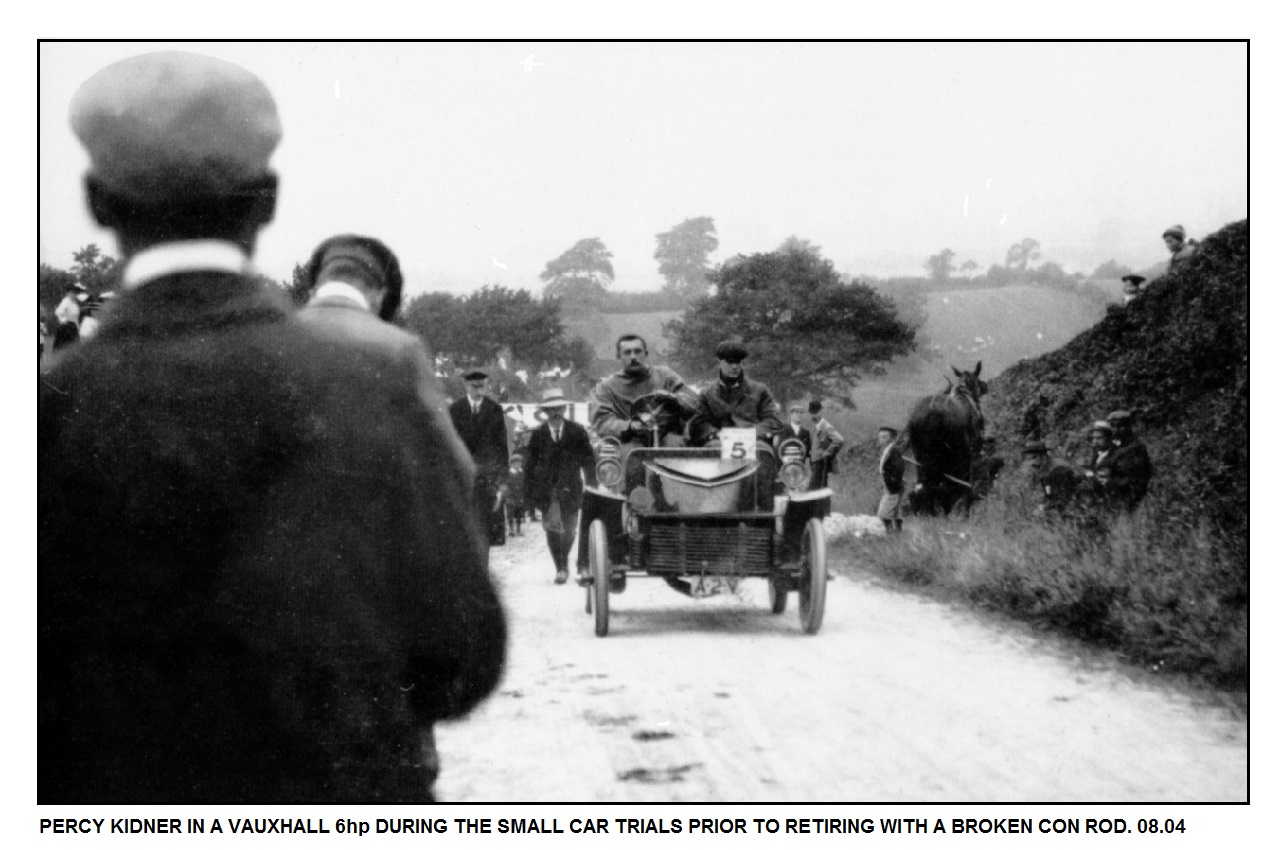

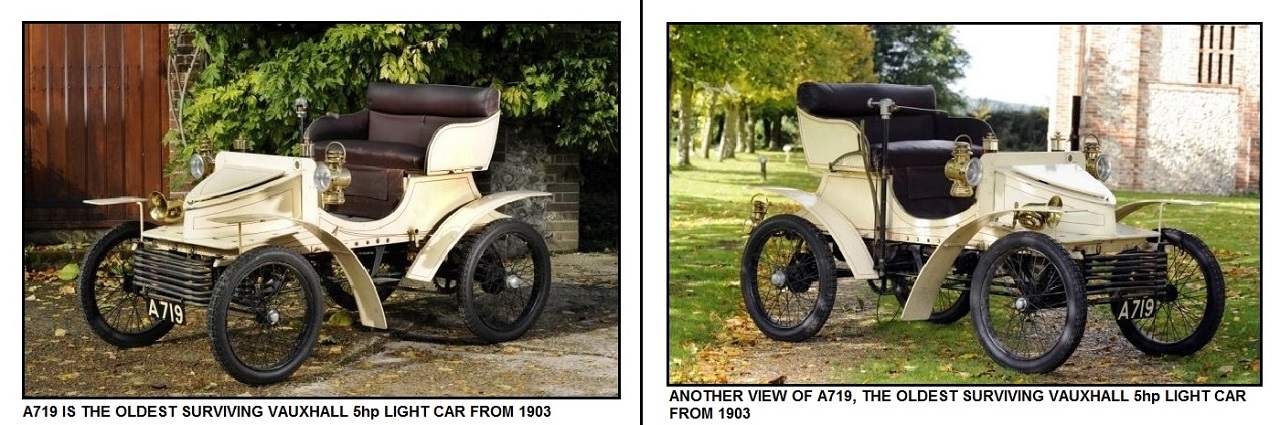

Because of his heavy involvement in the design & development JH Chambers wanted to call the car the “Chambers” which would also separate it from the company’s traditional marine products. Fortunately, his fellow directors overruled this and the car was announced to the press as the Vauxhall Light Car in April 1903, advertised from May with the first delivery made in early June. Initial demand meant the decision to limit the batch to twelve were soon dropped. A total of 46 cars were built in 1903 with a further 38 being built in 1904 until the 5hp car gave way to the 6hp. The 1903 cars were numbered from 031 onwards, so the car that the car that W Gardner purchased was numbered 036 making it the 6th car to be built. By the end of June 1903 both Hodges and Ash had purchased their own Vauxhall Light Car.

In August Chambers took a 5hp Light Car, the 13th to be built, on a sales trip to Ireland where he demonstrated the car to the Dublin motoring press who gave a favourable report on the car.

Reliability for cars at this time was not guaranteed and relied on considerable owner attention almost on a daily basis. The first dozen examples of the Light Car suffered a number of engine failures in the first few months of use, con rods broke, crankshafts fractured and big end bolts broke off. This was mainly due to the design and owner operation of the car rather than any quality issues in manufacture which was of the highest standard. The cars instruction book required owners to attend to the external engine bearing Stauffer greasers every 40 – 50 miles as well as a multitude of other tasks needed every 100 miles, owner neglect of this essential lubrication tasks would quickly lead to engine failure.

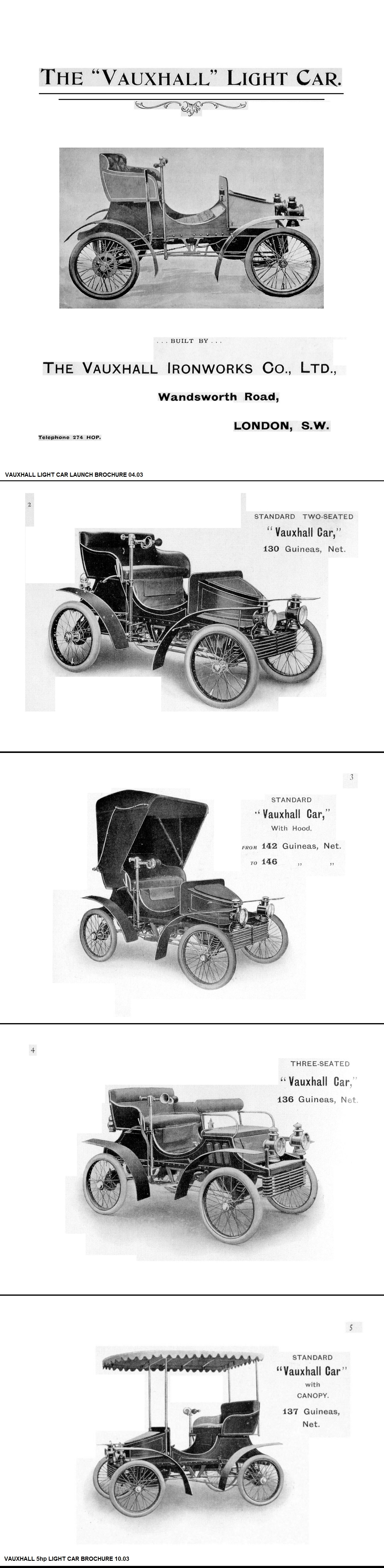

The Chrystal Palace Show in November 1903 was the first motor exhibition where Vauxhall cars were displayed, their stand (No110) featured four examples of the Light Car, 2 & 3 seaters with and without the newly available canopy which proved to be of little interest to customers and was dropped within a short time. Most sales agents for Vauxhall were in London or few other large cities but the most successful was Gould Brothers of Exeter. The first car ordered was in June 1903, number 0314, and a total of 15 by the time the 5hp & 6hp ceased production.