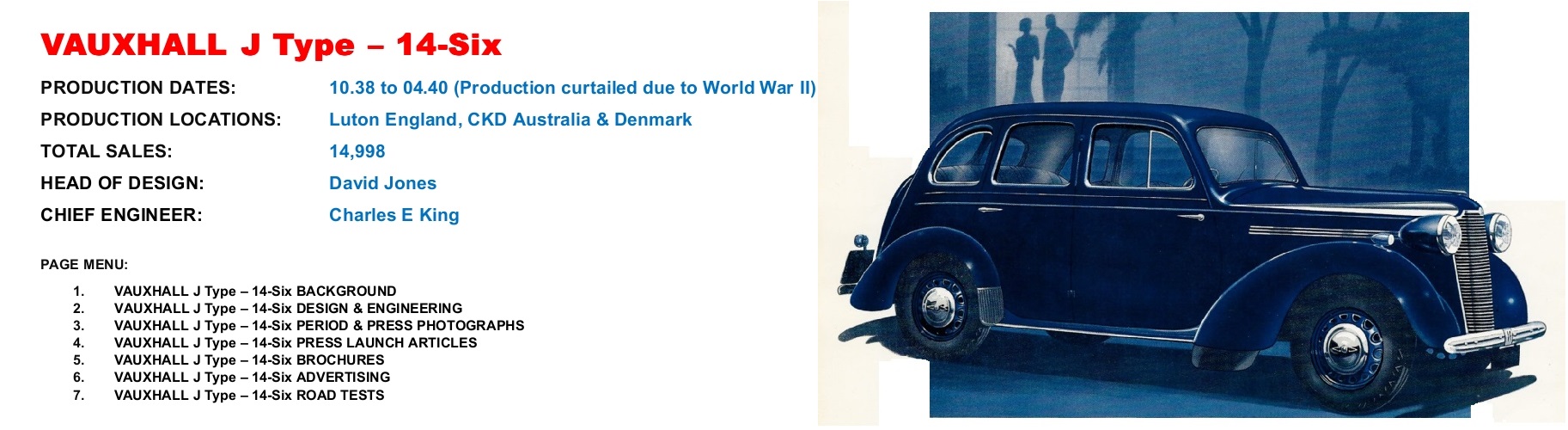

1. VAUXHALL J Type - 14-Six BACKGROUND:

Vauxhalls history in the 14hp class didn’t begin until May 1933 with the launch of The Light Six, which was also available as a cheaper 12hp model. The car was an instant success particularly the larger 14hp version and within a short space of time Vauxhall was challenging the established manufacturers for sales leadership in the 14hp sector of the British market, for a first attempt it was an enviable achievement. However, Vauxhall didn’t stop there, in 1935 The Light Six became the first British car to be fitted with a synchromesh gearbox and the 14hp sales leadership continued. In 1937 the Vauxhall 14hp featured 6 phase carburation, which meant 30mpg was achievable in normal driving by owners, and made the Vauxhall the most frugal 14hp car available – the sales momentum continued. Only in one year, 1937, did the smaller engine Vauxhall 12hp outsell the 14hp version and despite having so many advantages & unique features the 14hp Vauxhall was normally cheaper than most of its rivals – domestic or imported.

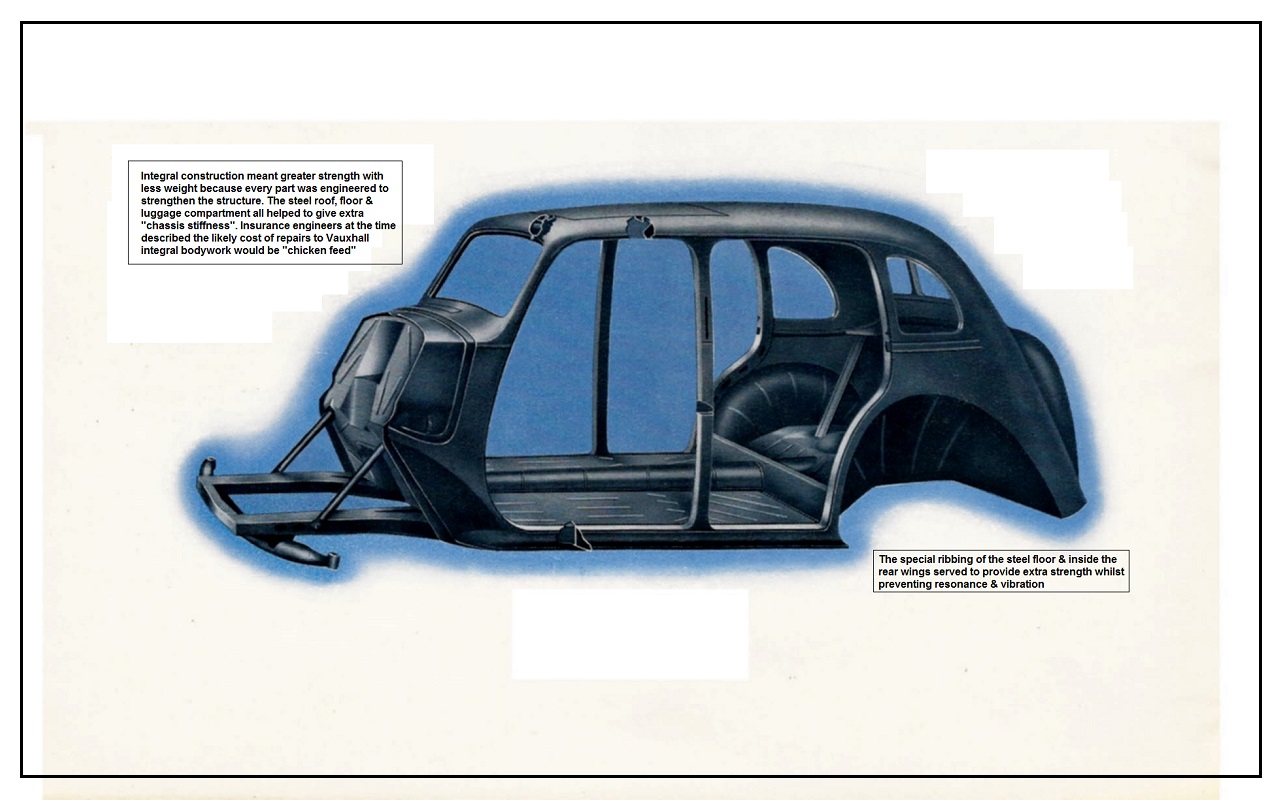

When it came to planning a replacement for the 14hp model Vauxhall knew it would have a very tough act to follow and needed to be something exceptionally good – and it was. Vauxhall had embarked on a radical model replacement programme that started with the new H Type 10-Four launched 1937 with unitary construction, the first British car to use it. This new body structure was to be applied in turn to each new model replacement and that included the new Vauxhall J Type 14-Six.

2. VAUXHALL J Type -

14-Six DESIGN & ENGINEERING:

The launch of the Vauxhall 10-Four in October 1937 was a bombshell for the British car industry and caused a sensation not least of which was the way it was put together. Unitary construction was seen by many as the future for motor car production and Vauxhall in Britain, along with Opel in Germany, were pioneers that paved the way for other volume car manufacturers to follow. Even as the new 10hp was being launched Vauxhall were busy working on the new I Type 12-Four along with a new J Type 14-Six model. The Styling Department at Luton had never been busier and, under the direction of the extremely talented David Jones, was now joined by Tony Cooke from Rolls Royce who was given responsibility for exterior design.

Unitary construction was partly made possible by significant advancements in electric welding processes with the welds in effect being as strong as the metal united. Today it is taken for granted but up until the start of unitary construction effectively a chassis was built and then a body was designed to fit, the shift to uni-body construction meant that the styling and engineering teams needed to work far more closely than ever before. It also meant new measuring technologies had to be developed to assess structural stiffness and tensile strength which were now critical to the whole design process. The benefits were many, cars could be made lighter but stronger, built quicker & for less cost with squeaks & rattles eliminated but it also had one major inherent weakness – rust. Corrosion would become a major issue for all car makers in the future and preventing it become a science on its own. Unitary construction would also make any styling changes or facelifts more expensive. Fortunately, Vauxhall had commissioned an expansion of the Engineering facilities, at a cost of £175,000, which became operational in 1938 and provided space for a total of 335 staff including David Jones’ Styling activities, the new building was identified as “V” block and would be home for all Vauxhalls Design & Engineering staff until 1964. At the time, it was one of the most comprehensive organizations in Europe for the investigation of problems relating to automobile design & manufacture.

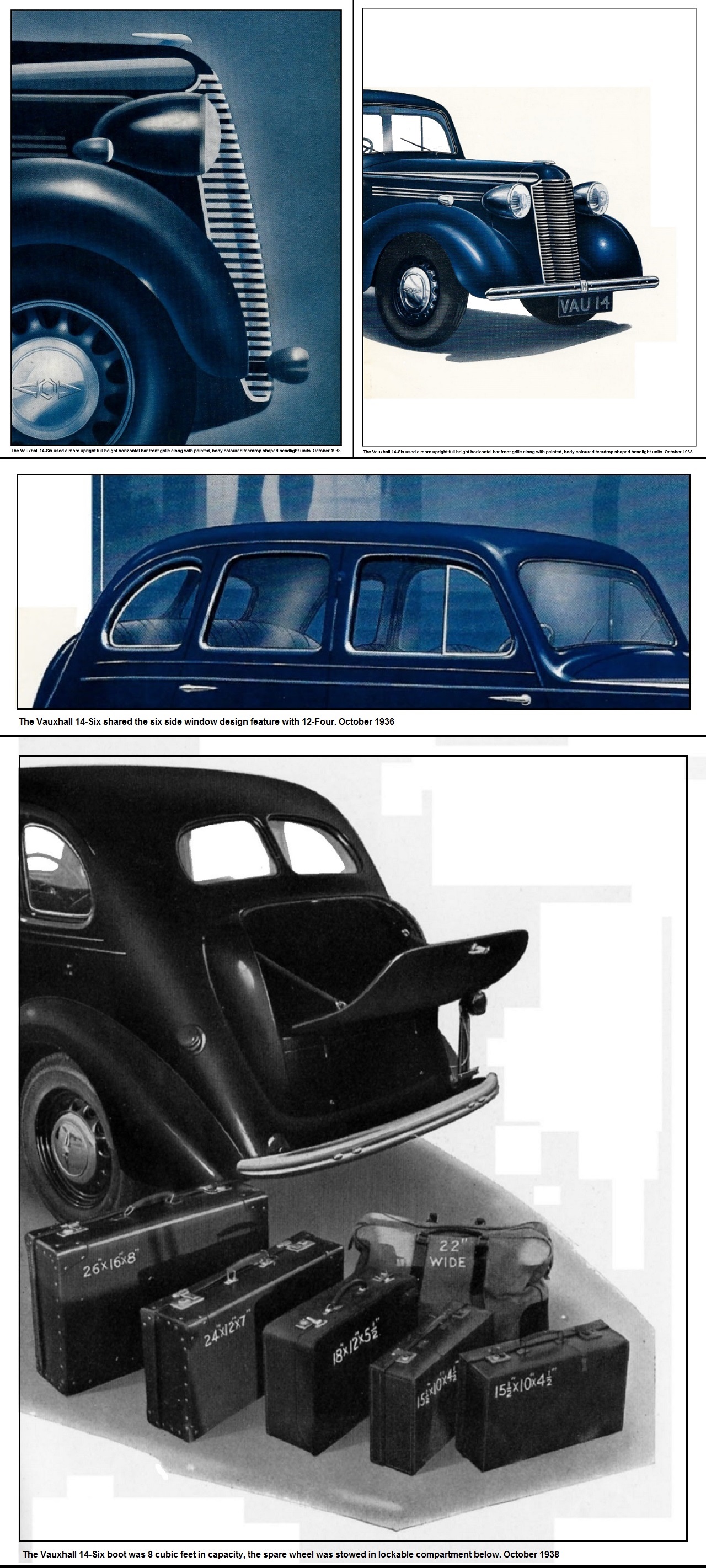

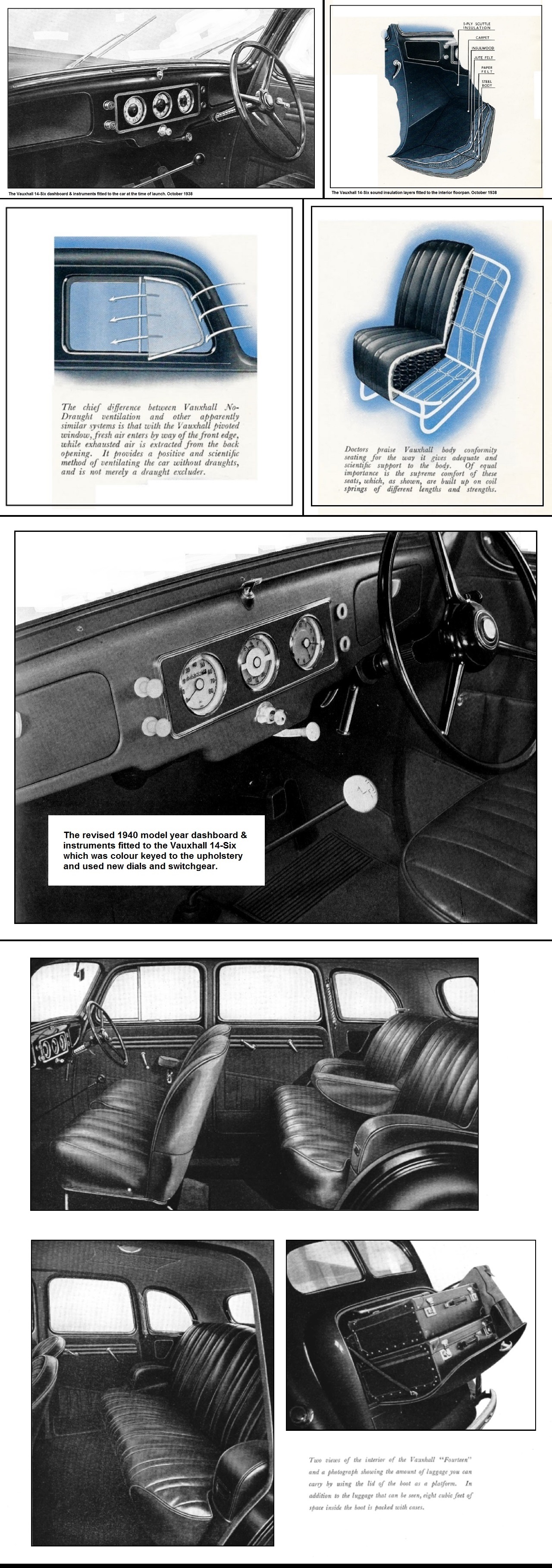

The J Type 14-Six styling was not, unlike its means of construction, in any way ground breaking but was modern, elegant, well balanced & of good proportions which belied the increase in size compared to the previous model. A more upright full height horizontal bar front grille was fitted along with painted, body coloured teardrop shaped headlight units and large sweeping front wings. The full width front bumper included the model name in the centre. There was a strong family resemblance to the car’s smaller siblings although only the 12-Four & 14-Six featured six light side windows, and the 14 was unique in having a divided rear window design. A major difference was the 14 was now a standalone model thus giving Vauxhall three distinct, but related offerings, in the 10, 12 & 14hp sectors of the market. Besides variations in length the Twelve was 2ins wider than the Ten and the Fourteen 2ins wider than the Twelve. In order to make savings on the tooling costs, the large dies used to form roofs and floor panels were divided longitudinally and inserts were used to adjust the widths between production runs. This ingenious expedient did not facilitate the task of making accurate pressings; other complications, used to vary the length of bodies, added to the problem. With practice, the manufacturing staff overcame the initial difficulties which were inevitable when both the product and a large part of the tooling used to make it are unfamiliar to the workforce and quality inspectors, but long before production processes began to run smoothly the Luton plant came under great pressure from Vauxhall Senior Executives to step the delivery of cars to impatient dealers and customers. In fact, Vauxhall had to scheduled-up 14-Six production 3 times to meet customer demand.

Inside there was a significant increase in passenger space, which applied to both front & rear legroom and front elbow room. The previous models body conformity front seats were carried over with armrests fitted to the front doors for the first time, rear passengers were treated to new foot rests and a centre armrest with all wearing surfaces finished in leather. There was also a great deal of attention paid to noise insulation with 5 separate under floor layers. No draught ventilation, a driver controlled rear blind and a sliding sunroof were standard fitment along with an adjustable steering column and self-cancelling indicators. The dashboard used at the launch was a plain, simple & practical with two large cubby holes either side and three large dials in the centre – a speedometer, a clock and a combined fuel & ammeter gauge which were indirectly lit at night to prevent glare. For the 1940 model year, a new dashboard of similar design was fitted with colour keyed finish, new style controls & instruments and lids fitted to the cubby holes either side. The interior was completed by twin sun visors, roof net & lamp, under dash handbrake lever, scuttle ventilator, pillar assist straps, the useless mechanical windscreen wipers, a total of six storage pockets, rear parcel shelf and three ashtrays (1 front & 2 flush mounted rear).

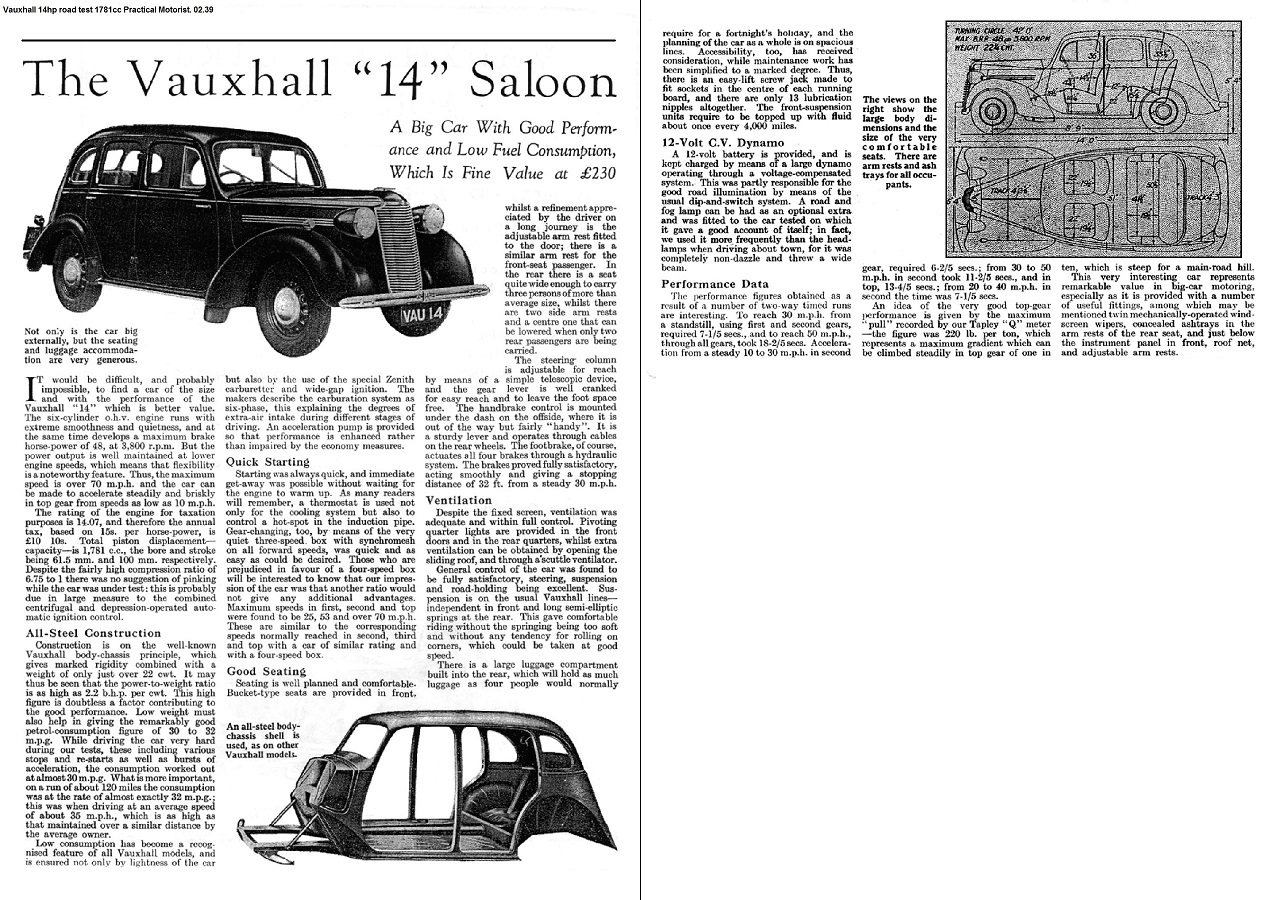

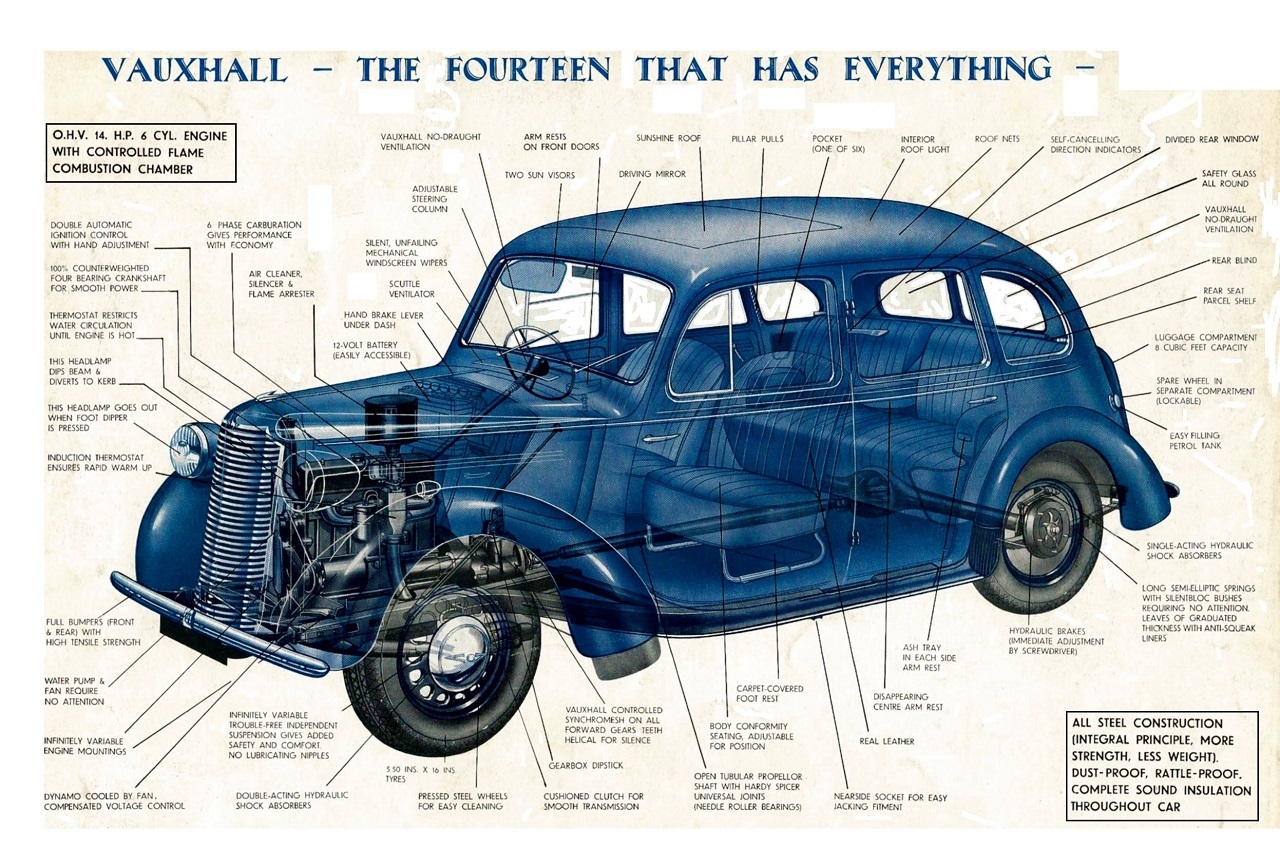

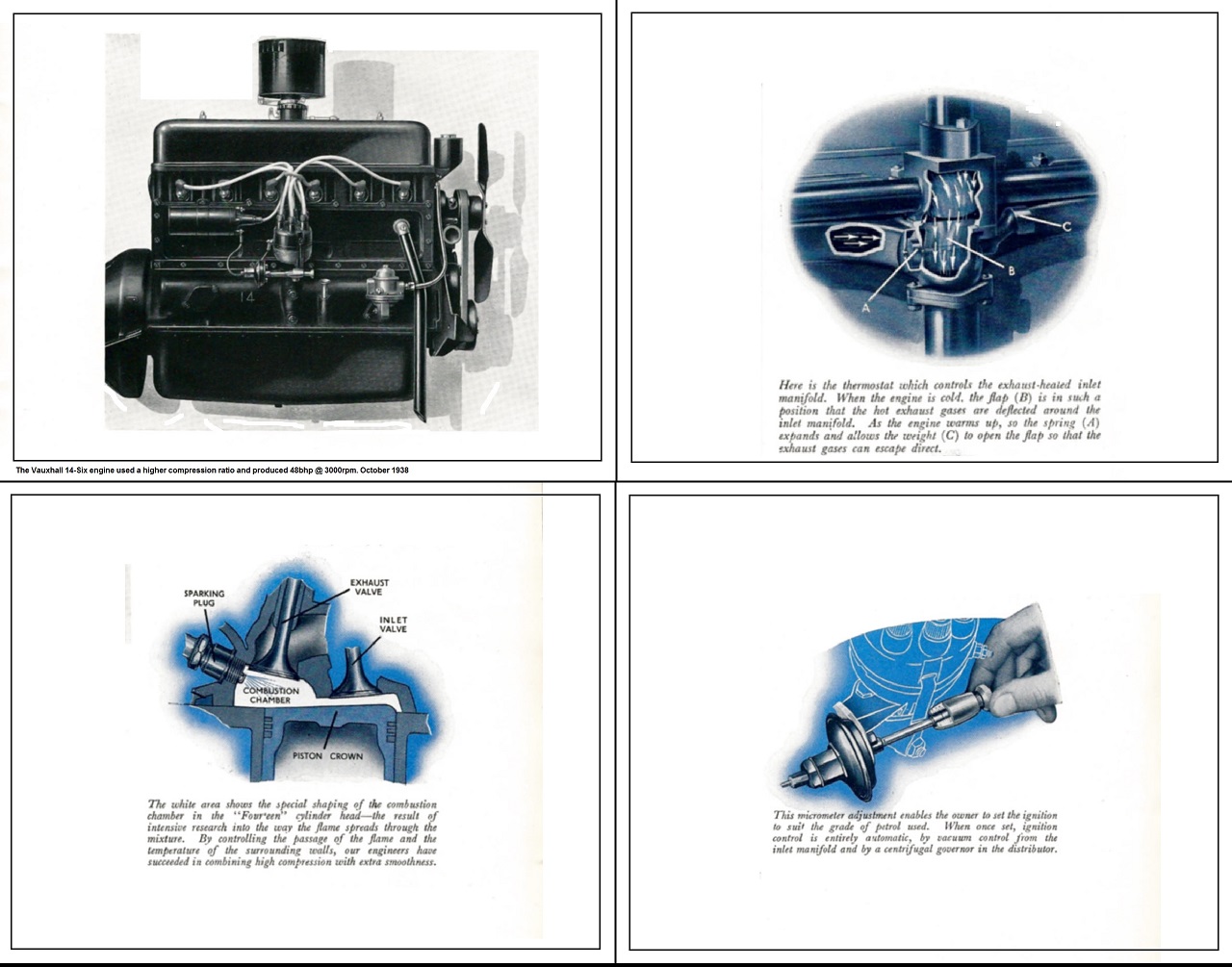

In terms of engineering the Vauxhall 14-Six utilised the same 6-cylinder 1781cc engine from the previous model but with the compression ratio increased from 6.25:1 to 6.75:1 and a revised camshaft which boosted power output to 48bhp @ 3000rpm, this peak was developed 600rpm lower than before and enabled a higher rear axle ratio to be used – 4.71:1 compared to 4.77:1 before. The gearbox was 3-speed like the H & I models but was the same unit fitted to the later versions of the Vauxhall 25hp and used synchromesh on all gears instead of just 2nd & 3rd. Braking was Lockheed hydraulic drum on all four wheels with a cable operated handbrake on the rear wheels only, this replaced the previous cable system bringing the car up to date and more than capable of coping with the impressive performance – a 70mph top speed & acceleration of 0 to 50mph in 21.6secs - flexibility was equally impressive, the car could slow to just above walking pace in top gear and pull away without protest. At the same time, in normal driving, the 14-Six would reward owners with an easily achieved 30mpg.

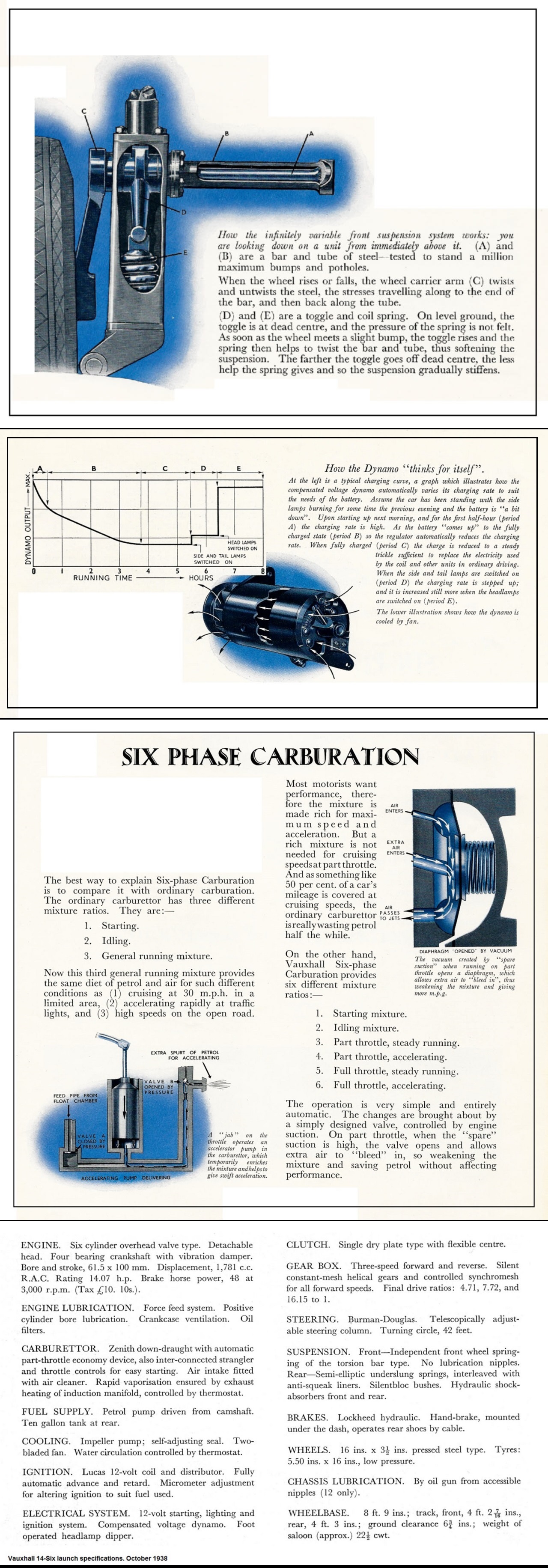

The wheelbase increased by 4ins and the track by 1ins which was beneficial for passenger space but increased the turning circle from 36.5ft to 42ft. The independent front suspension was the now familiar Vauxhall TT system adapted from the H and I Type models suitably calibrated for the heavier body of the J Type although it was approximately 150lbs lighter than the model it replaced. Rear suspension was by semi-elliptic underslung leaf springs with interleaved anti-squeak liners. With running boards a thing of the past front mudflaps were fitted as standard while the wheels & tyre sizes were unchanged.

Launched in October 1938 at the London Motor Show the £230 Vauxhall 14-Six was an instant hit with the motoring press & car buying public alike but it was an unfortunate time to launch a new car, there would be 1940 model year announcements but production was halted in April 1940 due to World War II. It is interesting to speculate what would have happened if the war effort had not got in the way, the car was streets ahead of any comparable rival and offered amazing value & specification.

3. VAUXHALL J Type -

14-Six PRESS & PERIOD

PHOTOGRAPHS:

4. VAUXHALL J Type - 14-Six PRESS LAUNCH ARTICLES:

6. VAUXHALL J Type - 14-Six ADVERTISING:

7. VAUXHALL J Type - 14-Six ROAD TESTS: